IP rating switchboards are necessary for manufacturers, but it’s important information for buyers too. The IP rating or IP code classifies the degree of protection provided by an enclosure. Switchboard manufacturers need to follow the standard, but contractors need to make sure they are selecting the correct board for their project and environment.

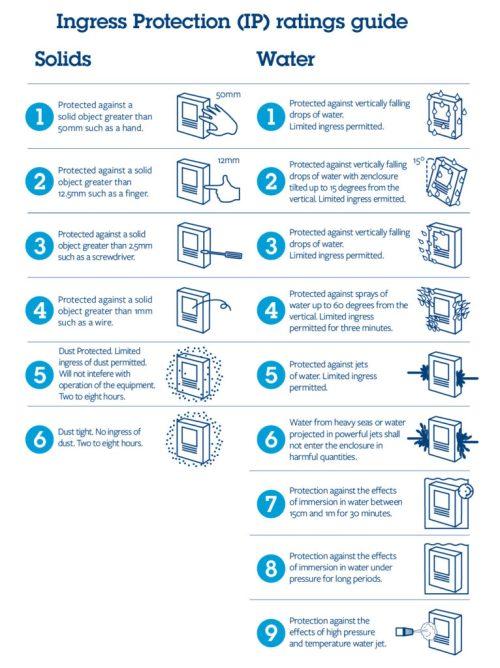

The IP system defines levels of sealing effectiveness against “ingress” i.e. intrusion from foreign bodies such as tools, dirt and liquid water.

Vague marketing terms such as ‘waterproof’, don’t give a clear definition of precisely where and to what extent an item can resist moisture ingress. An IP rating is designed to provide a far more specific account.

The universal IP rating system gives buyers confidence that the product is suitable for their environment and application.

The rating consists of the letters IP followed by two digits, the higher the number the better the protection.

Also, you need to consider the level of protection. A 0 rating offers no protection at all, while a 6 (for solids) and 8 (for liquids) offer airtight protection. Sometimes a number is replaced by X, which indicates that the enclosure is not rated for that specification.

So, what does all this have to do with you? There is a lot to take in, but we have you covered.

Australian switchboard manufacturers need to meet many standards. One of them being the IP ratings for switchboard enclosures and accessories. Enclosures and accessories must go through vigorous testing to ensure that they meet the minimum IP ratings. The design of systems and the nature of testing their boards for the IP ratings are specified in the AS 60529-2004.

Let’s use a couple of examples that might help clear things up.

The current Australian standard for main switchboards is the AS/NZS 61439. Although Australian standards list the minimum requirements (IP2X) it is essential for contractors to consider their environment. Where the switchboards are intended to be installed in a location with high dust, humidity, or potential water spray.

Design Switchboards and Distribution rate their Main Switchboards (MSB)s at IP40 to IP56.

Our design is fully compliant but the most important standard to note is AS/NZ61439.4 standards. The minimum in the standard is IP44. The DSD Temporary Power Board range is rated IP 44. Featuring a double-hinged door closing tightly with a seal against the enclosure, helping electrical contractors satisfy the regulatory requirements.

This board is versatile for many construction sites, but buyers still need to consider if it fit for purpose. We can provide you with many example projects for your consideration.

Are higher IP-rated enclosures better for switchboards? Not necessarily. It really depends on the environment where the switchboard will be located. Clearly, location is a key factor. Will there be a constant spray of water, the presence of dust and gases that could increase the pollution degree inside a switchboard? Naturally, there is a lot to consider in manufacturing higher-rated boards. But let’s review performance as an example.

It’s all about the enclosure. An IP56 rated enclosure restricts airflow which increases heat, affecting the performance of components such as busbar and circuit breakers. So, the higher IP rating the more enclosed the board will be, which will have a considerable impact on performance. You want to have the lowest IP rating possible, for the environment, minimising the need to upgrade components and increasing the cost of your board.

Simple, just ask us! Design Switchboards and Distribution have invested heavily over the years to develop manufacturing techniques that offer a correct degree of protection. It’s always worth asking how an enclosure’s IP rating is achieved.

While the rating system for an enclosure’s effectiveness is simple, the methods used by manufacturers to deliver such protection are the product of many years of R&D. Two enclosures that offer the same level of overall protection may achieve it in very different ways, which can have a big impact on the purchase cost and longevity of the product. Understanding the different manufacturing techniques is the first step in making the right choice.

Site By: Thrive